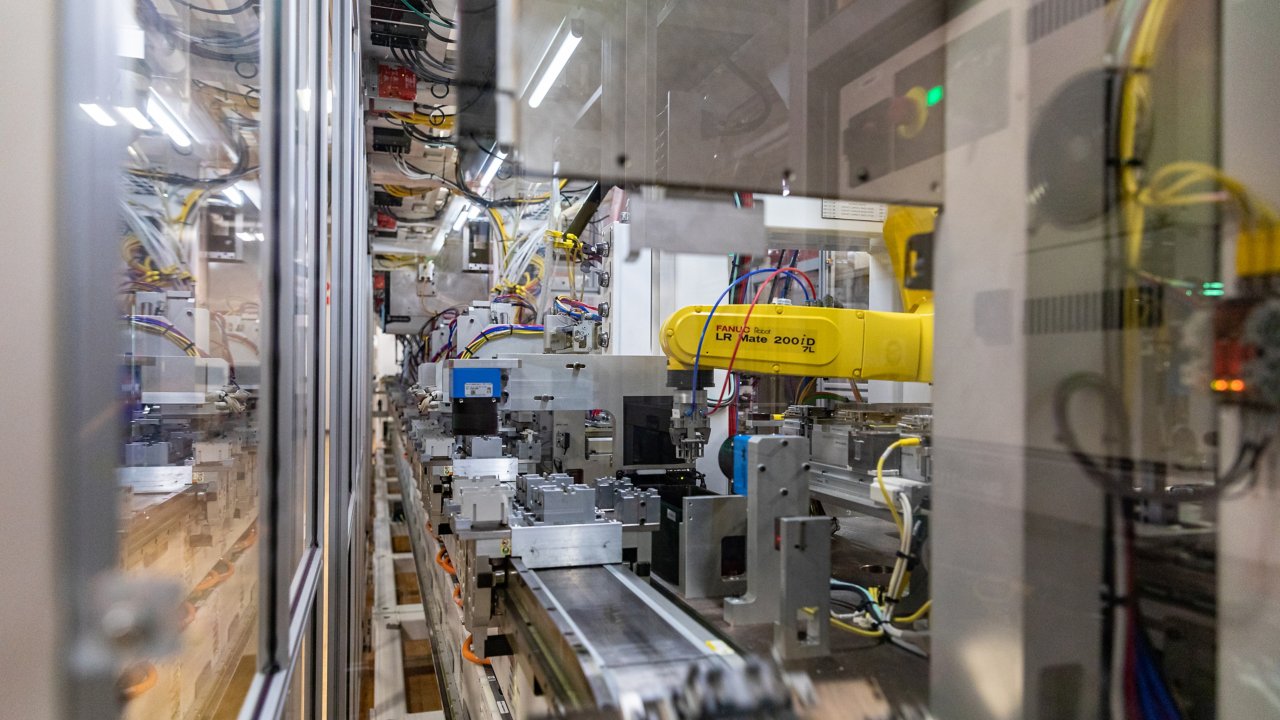

Meet the Technology Behind More Innovative Machines

Customers want more options and customized products. To accommodate the demand, systems must be flexible and quick to respond to production needs. With independent cart technology, you’ve got it covered. Curved or straight sections of track can be combined in endless combinations to suite your design and space requirements. Layouts are configured from a standard set of building blocks and can be adapted or expanded over time - giving you freedom of design to create your ideal system. And once it’s built, changeovers can be as simple as selecting another software-configured move profile.

Are you ready to reduce bottlenecks and increase output? Each cart in the system is its own controlled axis of motion. That means that the carts can intelligently speed up or slow down based on where other carts are in the system. The system also tracks what each cart is moving, so there’s no need to slow down for sortation. The result? Fluid motion that handles products more efficiently than ever before.

All motors and carts are rated IP65 or higher and can work together or independently to handle various payloads, which makes them a great choice for a wide range of applications. Systems can be purchased as fully assembled units, as individual components or as a mix of custom and standard parts so you always get just what you need.